Thermoforming film

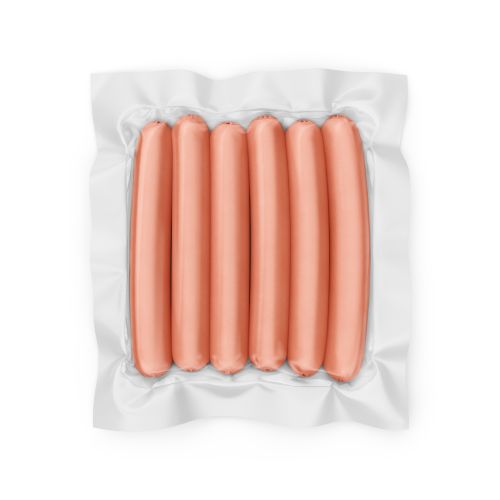

Thermoforming film is widely used in the food processing industry for its high-output capabilities. The film is heated and stretched to form a pocket. Once the product is in the pocket, the choice is yours: vacuum, gas flush, straight seal. The high-volume, high-speed capability is a go-to for boosting your packaging efficiency.

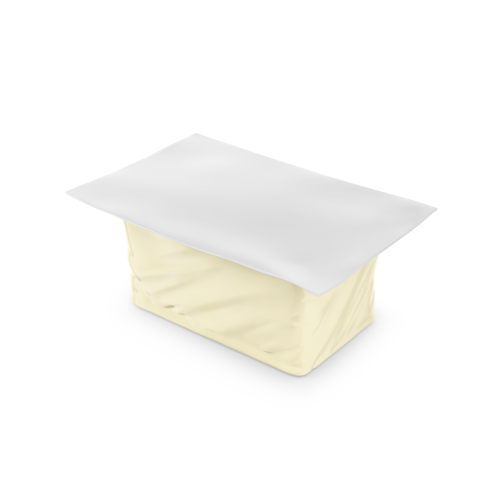

Flexible to semi-rigid film options make this the choice for fresh meats, seafood, cheeses, deli meats, and snacks. The thermoforming films even have options for re-seal functionality, allowing continued at-home freshness for your customers for multi-portion packs.

Thermoforming film is widely used in the food processing industry for its high-output capabilities. The film is heated and stretched to form a pocket. Once the product is in the pocket, the choice is yours: vacuum, gas flush, straight seal. The high-volume, high-speed capability is a go-to for boosting your packaging efficiency.

Flexible to semi-rigid film options make this the choice for fresh meats, seafood, cheeses, deli meats, and snacks. The thermoforming films even have options for re-seal functionality, allowing continued at-home freshness for your customers for multi-portion packs.

Thermoforming Film

Features & options

Exceptional puncture resistance

Tight seal, even over grease and oils

Ultra high clarity

Deep draw depth

Fully customizable sizes and printing

Clear and coloured film in stock

THERMOFORMING

Film types

High barrier film

Features & benefits

High oxygen and moisture barriers to extend shelf life and maximize freshness.

Application: Fresh and frozen meats, prepared meals, fresh pasta, cheese, pet foods, and seafood.

Breathable film

Features & benefits:

For fresh and smoked fish that need oxygen permeability to prevent foodborne illnesses and food-spoiling bacteria.

Application: Fresh and smoked fish, and fresh poultry.

Cook-in film

Features & benefits

Certified films for long-term heat exposure in cooking and microwaving applications.

Application: Cooked and processed meats and seafood, cooked pet foods.

Semi-rigid film

Features & benefits

A thicker film for a pack with a more rigid structure. High production capacities for packs that hold their shape.

Application: Fresh and processed meats, sliced cheeses, and fresh and smoked fish.

THERMOFORMING FILM

Opening options

EZ peel

Enhance customer experience and ease-of-use with film that peels easily. There are a wide range of options and materials for easy-open packages.

Peel reseal

Prevent moisture loss and keep multi-portion products fresh. Die cut windows allow your packaigng to be resealed to keep out the atmosphere of the fridge.

Lock seal

A tight seal to protect products and keep that freshness locked in.

THERMOFORMING FILM

Applications

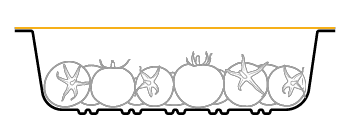

Ambient

packaging

Ambient packaging

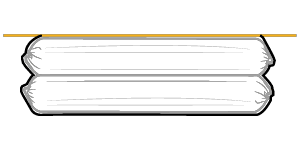

Vacuum packaging

Vacuum packaging

Modified atmosphere packaging (MAP)

Modified atmosphere packaging (MAP)

Other

Films

Have a project in mind?

Our packaging experts are happy to help. We can provide free consultations and pricing for tailored, high-quality solutions.